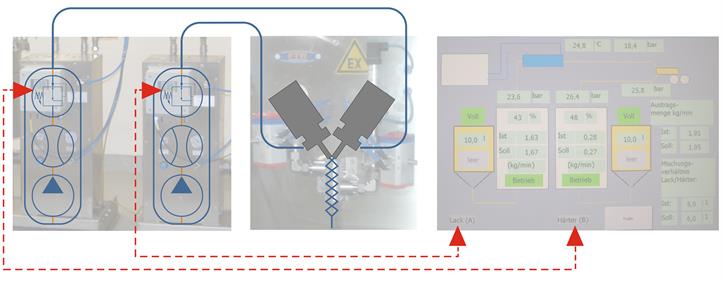

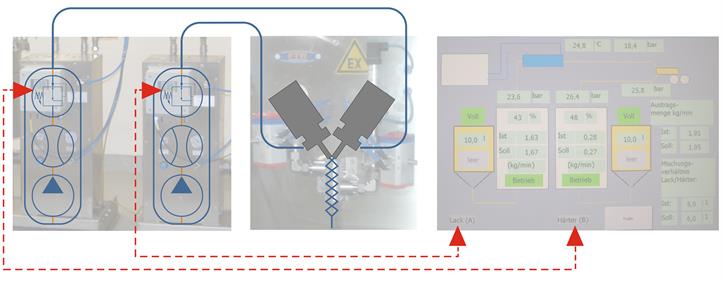

The diagram shows the implemented 2K system of a painting plant. Two standard UCP dosing

pumps are integrated in this system. The controls of the UCP continuously transmit the two A and

B component volume flow rates (actual values) to the higher-level PLC control of the painting

plant. PID controllers apply dosing pressure to keep the volume flow rates of the two components

within the specified nominal values. This constantly compensates changes in the viscosity of the

two components. A static mixer is used to mix the two components. The dosing system operates

in a pressure range of 10 to 60 bar and a paint mixture volume flow rate of up to 8 l/min.